Lista de Productos

Bottle production line IV

Description

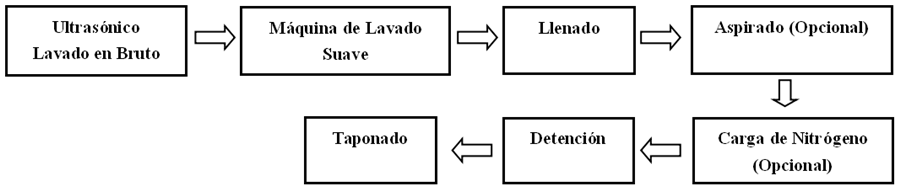

The Bottles IV production line is mainly used for glass bottle solutions from 50 to 500 ml, and performs the functions of cleaning, filling, capping, screwing, etc. It can be used for the production of glucose, antibiotics, amino acids, fat emulsions, nutrient solutions, biological agents and other liquids.Diagram

Main Characteristics Of The Production Line Of IV Bottles

1. The bottle washing machine has a new design, which is that the rough washing follows the same direction both in the entrance and the exit of bottles, thus saving operators and workspace.2. The bottle outlet of the rough wash and the soft wash receives the bottles twice, thus avoiding to turn them break.

3. The bottle washing machine uses intermittent washing to prevent contamination caused by continuous washing.

4. Bottle entry is done by combining the bottle hook and the guide plate, thus preventing the bottle from spinning and making the process more reliable.

5. Wash water can be recycled and filtered, thus reducing water consumption.

6. The filling is based on the current theory of time and the constant. The filling volume can be accurately adjusted by the computer.

7. The machine does not fill without a bottle. CIP / SIP systems available.

Main Characteristics Of The Production Line Of IV Bottles

| Main points | Main Content | |||

| Model | BPY50 / 500-120 | BPY50 / 500-200 | BPY50 / 500-300 | BPY50 / 500-600 |

| Bottle Size | 50 ml, 100 ml, 250 ml, 500 ml | |||

| Production capacity | 80 to 120 bottle / min | 120 to 200 bottle / min | 200 to 300 bottles / min | 300 to 600 bottle / min |

| Electrical Capacity | 35 kW | 37 kW | 45 kW | 55 kW |

| Compressed Air Consumption | 4³ / h (0.6 MPa) | 5³ / h (0.6 MPa) | 6³ / h (0.6 MPa) | 7³ / h (0.6 MPa) |

| Water consumption | Running water: 200 ml / bottle Purified water: 80 ml / bottle Injected water: 120 ml / bottle 0.2 MPa | |||

| Total Size (mm) | 17800 × 6000 × 2300 | 19000 × 6000 × 2300 | 24000 × 7000 × 2300 | 24000 × 7000 × 2300 |

Spanish

Spanish French

French Arabic

Arabic