Lista de Productos

LVP XGF Washing-Filling-Sealing Machine

Description

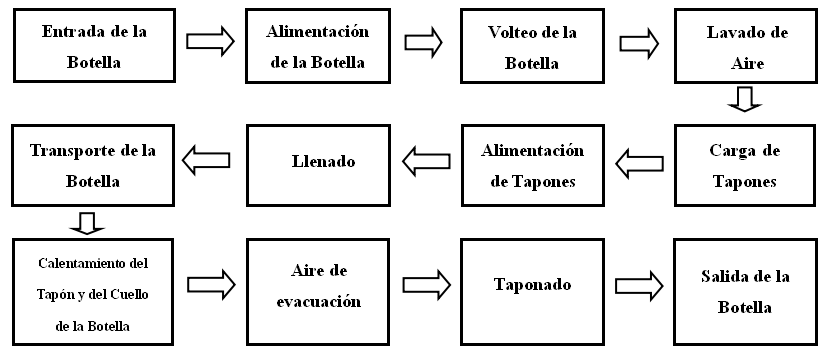

The LVP XGF washer-fill-sealing machine is composed of three sections: ion-flow washing or ion-stream washing plus water, constant pressure filling and hot sealing. The XGF machine automatically completes the processes for feeding the bottle, bottle inlet, bottle flushing by manipulator, reverse ionic flow washing, bottle transport, fixed volume filling, cap sorting, simultaneous heating of the cap and Bottle neck, air removal, hot sealing, line bottle outlet, etc.Use

The XGF machine is mainly used to wash, fill and seal the production of soft plastics and rigid bottles of large parenteral volume, such as glucose infusions, sodium chloride, injections of sodium chloride and dextrose, injections of metronidazole, etc.Diagram of the LVP XGF Washing-Filling-Sealing Machine

Features of the LVP XGF Washing-Filling-Sealing Machine

1. Wash-fill-seal production area of integrated compact design2. Suitable for intravenous bottles of different shapes, round or flat

3. Alarm and stop of the machine in case of any failure

4. PLC control, all operations can be set up, changed and stored in a file

5. Sanitary Cleaning and Sterilization System (CIP / SIP) available

settings

| Has | Data |

| Production Capacity | From 2,000 to 20,000 bottles / hour |

| Specifications | 50 to 1000 ml in round or other bottles |

| Bottle washing | Flushing by single stream or by flushing more water |

| Main fill volume | Large volume infusions like infusions |

| Margin of filling error | + 1% |

| Temperature of filling and pressure flow | From 40 to 55º C From 0.6 to 2kg / cm² |

| CIP / SIP | 125º C --30min |

| Air Consumption (clean air) | Pressure from 0.6 to 0.8 Mpa 180 (120) m / hr / hr |

| Cooling water | 250 L / h, from 15 to 20º C |

| Noise | Max.75dB |

| Electrical Capacity | 18 to 35kW |

Spanish

Spanish French

French Arabic

Arabic